Why finned tube surface area is important?

As the name describes, the purpose of a fin tube heat exchanger is to transfer heat. But you need to know how much heat you want exchanged and that requires a certain amount of area to accomplish the heat transfer.

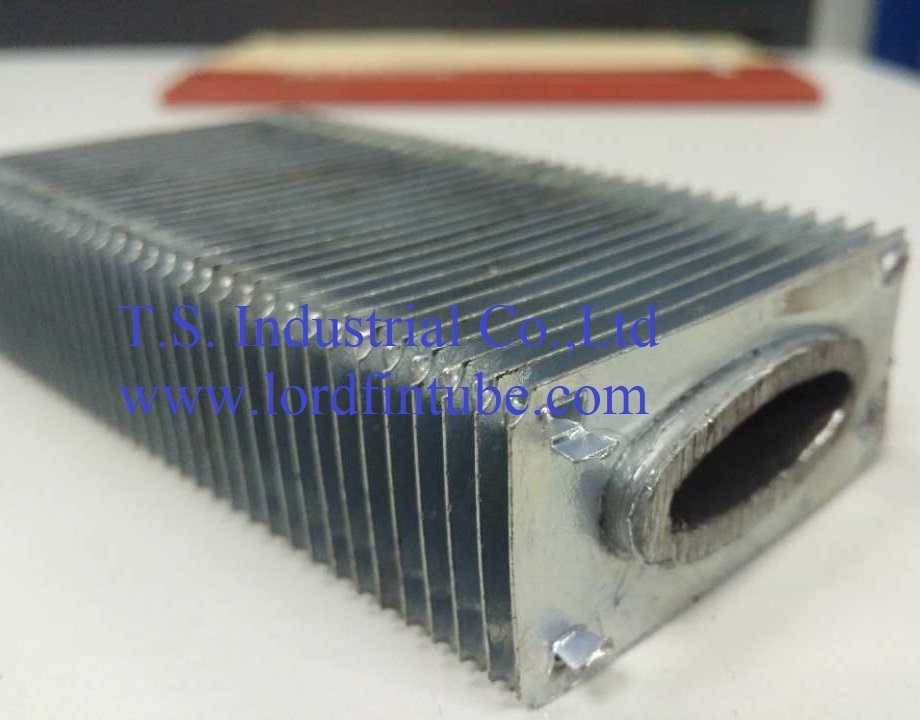

The purpose of fin tubes, as well as enhanced surface tubes and formed and dimpled tubes, is to add more area to optimize the exchange of heat transfer. The fins in a finned tube are essentially adding heat transfer area to the device. A larger area means greater heat transfer capabilities.

How do you determine the surface area of a fin tube? Because after all, the amount of surface area determines the heat exchange capabilities of your fin tubing. Surface area is an essential engineering characteristic of a fin tube’s performance.

How do you determine the surface area of a fin tube? Because after all, the amount of surface area determines the heat exchange capabilities of your fin tubing. Surface area is an essential engineering characteristic of a fin tube’s performance.

the size of the fin tube surface area of your heat exchange is directly proportional to the demand for heat transfer required.

Having too many fins too close together on a tube also risks fouling of the fins, with the fins becoming clogged with sediments or minerals in the water or fluid going through the tube. This effectively creates an insulating layer that blocks the exchange or flow of heat.

So not only do you need a precise amount of fin surface to ensure efficient heat transfer, but the fins themselves require space between each fin to allow for free fluid exchange.

Do you know How do you calculate the surface area of a fin tube?

Comments

Post a Comment