1. What is a finned tube bundle?

Finned tube bundle composed of multiple finned tubes arranged according to certain rules is called finned tube bundle. A finned tube heat exchanger can be composed of one or more finned tube bundles.

2. What is the composition of the finned tube bundle?

Finned tube (multiple tubes): basic element of heat transfer.

Tube box (header) or tube plate: the header, elbow or steel plate connecting the two ends of the fin tube.

When the finned tube is connected with the header or tube sheet, the spacing between the finned tubes is fixed, and the tube box forms a continuous flow channel for the fluid in the tube. Frame: support and fix the whole finned tube bundle.

3. Finned tube bundle arrangement?

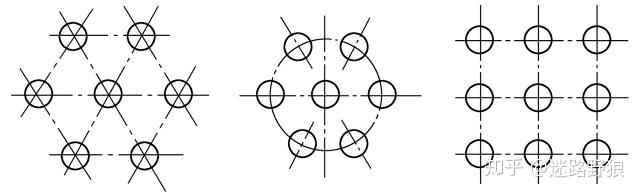

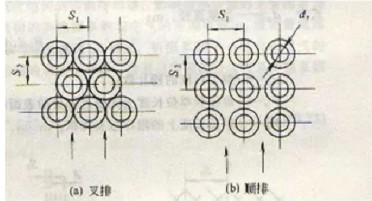

In a finned tubes bundle, the selection of fin tube arrangement is crucial. There are two types of arrangement: staggered and sequential. The so-called staggered arrangement refers to the cross arrangement of pipes in the air flow direction, while the in-line arrangement refers to the sequential arrangement of pipes in the air flow direction.

The following figure refers to that the finned tubes with different fin structures, such as rectangular fins or integral plate fins (also called plate fins), can also be divided into staggered and in-line.

The arrow in the figure represents the flow direction of the fluid outside the pipe, S1 represents the transverse pipe spacing, and S2 represents the longitudinal pipe spacing.

Advantages and disadvantages of in-line and staggered arrangement:

Advantages and disadvantages of in-line and staggered arrangement:

Sequential arrangement: when the fluid flows around the outside of the pipe, the disturbance is small and the heat transfer coefficient is low, but the advantage is that the resistance is small.

Cross row: when the fluid flows around the outside of the pipe, it is subject to large disturbance and high heat transfer coefficient, but the disadvantage is that the resistance is large. When there is no strict restriction on the resistance drop, the staggered arrangement should be preferred; When the required resistance drop is very small, the sequential arrangement scheme shall be selected.

4. Structural form of finned tubes header

If the arrangement form of finned tubes bundles (in sequence or in staggered arrangement, and the selection of tube spacing) is mainly determined by considering the heat transfer requirements of the fluid outside the tube, then the form and structure of the tube box are mainly based on the pressure and heat transfer requirements of the fluid inside the tube.

Generally, the following principles shall be followed:

(1) If the pressure of the fluid in the pipe is relatively high, the large diameter round pipe is generally selected as the pipe header. For example, in boiler applications, almost all use circular tubes as tube boxes/tube header.

(2) In the application of air cooler, square tube header is preferred.

The square tube header has the advantage that multiple rows of fin tubes can be connected at the same time. When there is steam condensation in the pipe, a large steam space is required, and it is necessary to connect a tube header with multiple rows of pipes.

(3) When the temperature difference between the inlet and outlet of the fluid in the pipe is large, the pipe box may be deformed due to the different thermal expansion of the pipe bank. In this case, the decomposition type pipe box should be used.

(4) Except for the first and last rows of tube bundles, which must be connected by corresponding pipe boxes, other rows should be connected one-to-one by elbows.

Comments

Post a Comment