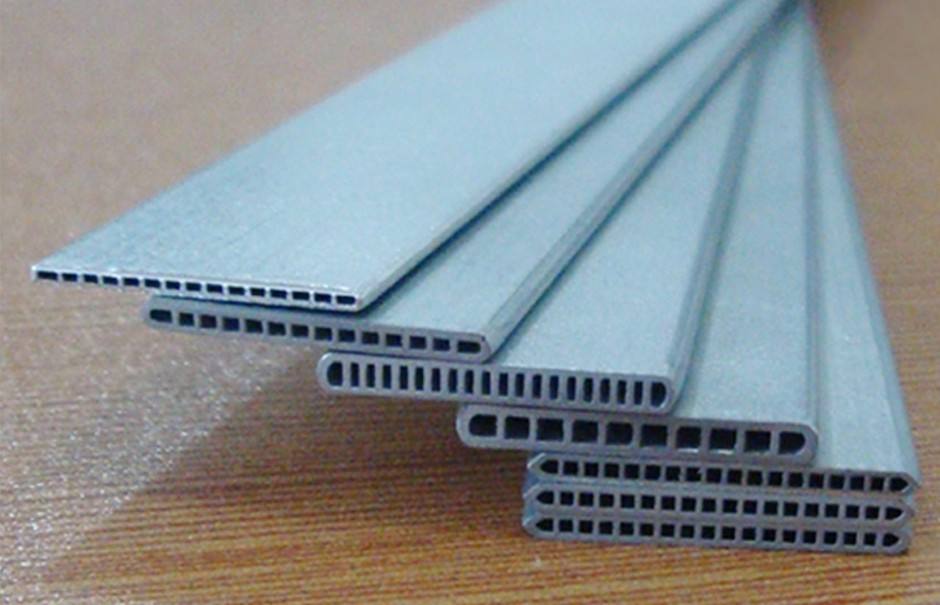

The Multi-Port Extrusion Tube (MPE Tube), also called Acer micro channel aluminum flat tube;micro-channel tube, is a highly refined quality product characterized by the following properties:

● Low energy costs

● High performance

● Low space and weight

● High corrosion and pressure resistance

● High recycling value

● Pressure drop and silent solution

● Low refrigerant fill

Beside increased global performances, an all-aluminum brazed heat exchanger using MPE will also present better corrosion resistance. MPEs are primarily used for the following applications:

● Condensers

● Evaporators

● Heater cores

Dimensions

MPE | Category | Range |

Width | 8mm-40mm | |

Thickness | 1mm-5mm | |

Wall thickness | 0.18mm-0.8mm | |

Thickness of zinc spraying | 3g/mm2-20g/mm2 | |

Fixed length | 100mm-4000mm | |

Number of Pores | 3-40 | |

Other non-standard dimensions are available upon request. | ||

Micro-multiport extrusion tube

Micro-multiport extrusion tube (MPE tube) is mainly used for the production of heat exchangers. Due to its high corrosion-resistance & good heat conductivity, MPE tube is particularly well suited for the use in evaporators & condensers with refrigerant R134-A. It is the trend to use new refrigerant R744 (CO2) in future, MPE tube is required increased burst strength and better heat conductivity for an optimized product size. To meet the market requirement, APALT developed zinc-coated & flux coated MPE tubes, it can be supplied in coils, or fixed length by non-cutting separation method.

Alloy: 1100、1050、3003、3102 and so on

Temper: H112

Common sizes: 18X1.2, 18X2.2 & 15X2 and so on

Application: Condenser, evaporator

Publisher:Lord Fin Tube

Comments

Post a Comment