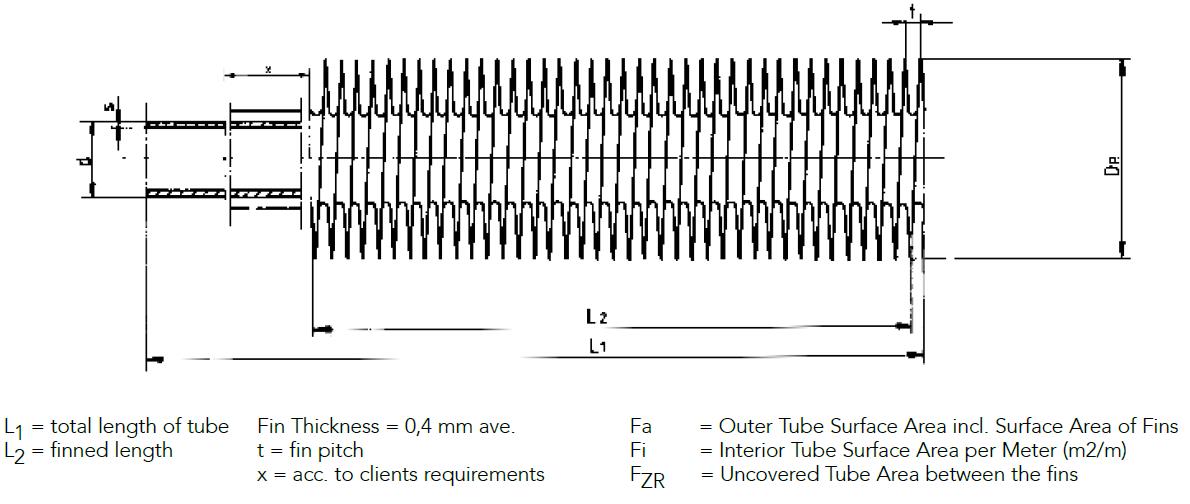

HYS Type Fin Tube|Extruded Serrated Finned Tube

HYS type fin tube also named extruded serrated finned tube. A smooth core tube is inserted into an aluminium tube and then fins are extrudes out of the aluminium tube. Advantages: Bond ot outer and inner tube removes the risk of loss of contact due to thermal stress, fins are more rigid,Core tube extensively protected against corrosion by the aluminium sleeve.

As per type HY, but fins are serrated. Advantages: Higher heat transfer coefficient, for same pressure drop compared with HY fin.

HYS Type Fin Tube Material Combinations

Core Tube: Carbon steels, low-alloy steels, stainless steels, brass,copper, copper-nickel alloys, aluminium bronze, nickel-alloys,as well as exotic grades. Core tubes with extremely thin wall materials can be applied.

HYS Fin Tube Exterior Tube & Fins: Generally Aluminium (different grades available)

HYS Type Fin Tube Fields of Application:

HYS Type Fin Tube Fields of Application:

• the petroleum, chemical and petrochemical industries

• natural gas treatment

• the steel industry: blast furnace and converter cooling systems

• power generation: steam turbine exhaust condensing

– contact condensing with cooling of circulating condensate

– fossil and nuclear power plants

• air conditioning (freon, ammonia, propane)

• incineration of household refuse

• compressor coolers, ect.

HYS Type Fin Tube Manufacturing Process

A polished and deoiled base tube is set in an aluminium sleeve. The whole goes through the fin-machine wich consists of three spindles set at 120° each on bearing a stack of plates. These plates, stacked in from and diameter first build

the fin, then bond the outer and inner tubes together. In certain cases (high air speed) the fins are serrated after fin process so as to increase the heat transfer coefficient.

HYS Type Fin Tube Advantages

1) HYS Type Fin Tube Thermal

The bonding of the outer and inner tubes removes the risk of loss of contact with the aluminium due to thermal stress.

Maximum operating temperature: 250° C. The transfer coeffcient remains steady. Additionally as the outer sleeve is continuous no electrolytic couple is created.

2) HYS Type Fin Tube Mechanical

The fins are more rigid and stand the handling shocks better,compared to types „G“ an „L“.

In order to forward you a promt offer we would be pleased to receive you detailed enquiry containing:

• Base tube material and quantity

• Base tube size

• Fin material

• Fin type

• Fin diameter or height

• Fin thickness

• Fins per inch, meter or fin pitch

• Lenght of plain, unfinned ends (nessesary to roll or weld the tubes into tubeplate or assembly)

Comments

Post a Comment