What is laser welded carbon steel finned tube?

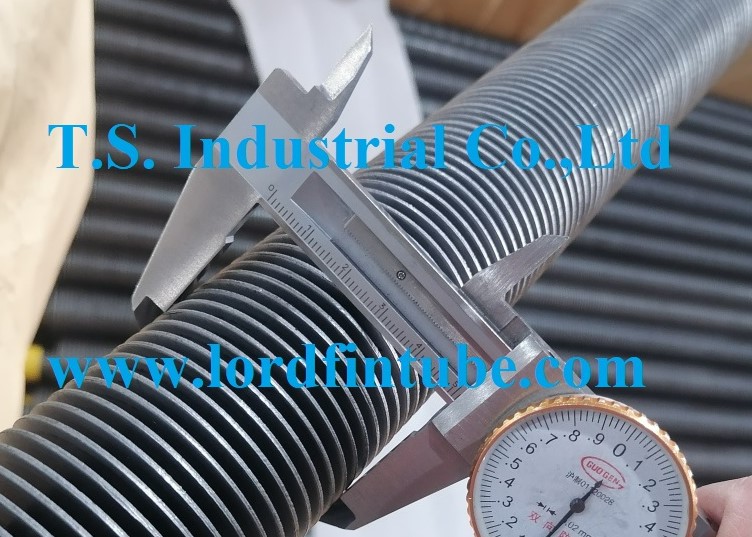

Laser welded carbon steel finned tube adopts the laser welding process, which can weld the carbon steel tubes and carbon steel fins with thinner wall thickness and denser fin pitch. The thinner bare tubes and denser fins can improve the heat transfer efficiency.

Why use laser welded carbon steel finned tube?

At beginning, laser welded finning machine mainly welded stainless steel tube with stainless steel fins. During the process technolgy developing, carbon steel tube with carbon steel fin become encomical, such as lower weight and higher heat transfer capacity. In some occasions, Laser welded carbon steel finned tube can replace the high frequency welded solid finned tubes.

Laser automatic welding spiral fin welding machine uses high energy density laser to weld finned tubes. The laser heat input is less, the effect is accurate, and the fin after welding has little effect on the laser heat. The whole equipment is fully automatic finned tube welding, with fins wound on one side and laser welded fins on the other side. During the entire production process, the operator only needs to load the material at the beginning of welding and unload it after the welding is completed. In normal operation, the steel strip is automatically wound on the steel pipe, and the automatic sheet winding, laser automatic welding, and high degree of automation are achieved.

Bare Tube OD mm | Bare Tube WT mm | Fin Pitch mm | Fin Height mm | Fin Thk mm |

Φ10 | 1.2-2 | 2-3.5 | <5 | 0.3-1 |

Φ12 | <6 | |||

Φ16 | <8 | |||

Φ19 | >1.0 | 2-5 | <9 | 0.5-1 |

Φ22 | >1.2 | 2-5 | <11 | |

Φ25 | >1.3 | 2-6 | <12.5 | |

Φ28 | >1.5 | 2-8 | <14 | 0.8-1.2 |

Φ32 | >1.5 | 2-8 | <16 | |

Φ38 | >1.8 | 2-10 | <19 | |

Φ45 | >2 | 2-10 | <23 |

Spiral finned tubes have always been produced by high frequency welding, brazing or inlaying. This traditional production process makes the heat transfer and cooling efficiency of the finned tube not very high, and there will be weak welding and de-soldering. More importantly, after high-frequency welding, the temperature is too high and the thermal effect is too large, which easily causes the finned tube to rust, which limits the use environment of the finned tube. In a corrosive environment, the finned tube will be corroded after a short period of use. Even if the stainless steel finned tube is welded by high frequency, it cannot meet the requirements, mainly because the fins absorb too much heat and the temperature is too high, which affects the atomic arrangement of the stainless steel. Temper stainless steel, easy to rust and reduce corrosion resistance. Laser welding does not need to consider such issues at all. Laser welding is done in an instant, and the welded fins have no effect on heat recovery. The corrosion resistance of stainless steel does not decrease, so in strong acid and alkali environments, laser welding finned tubes should be competent.

Spiral finned tubes have always been produced by high frequency welding, brazing or inlaying. This traditional production process makes the heat transfer and cooling efficiency of the finned tube not very high, and there will be weak welding and de-soldering. More importantly, after high-frequency welding, the temperature is too high and the thermal effect is too large, which easily causes the finned tube to rust, which limits the use environment of the finned tube. In a corrosive environment, the finned tube will be corroded after a short period of use. Even if the stainless steel finned tube is welded by high frequency, it cannot meet the requirements, mainly because the fins absorb too much heat and the temperature is too high, which affects the atomic arrangement of the stainless steel. Temper stainless steel, easy to rust and reduce corrosion resistance. Laser welding does not need to consider such issues at all. Laser welding is done in an instant, and the welded fins have no effect on heat recovery. The corrosion resistance of stainless steel does not decrease, so in strong acid and alkali environments, laser welding finned tubes should be competent.

Advantages of laser welded carbon steel helical fin tubes:

1. Laser welded carbon steel finned tube adopts continuous laser welding machine to complete the welding of finned tube automatic winding device. The fins are welded very firmly. Fins and tubes are welded without missing welding.

2. Laser welding of carbon steel finned tubes is to dissolve the base metal of fins and tubes to realize welding. The strength of the finned tube can reach more than 600MPa.

3. Laser welding carbon steel finned tube using automatic finned tube laser welding machine adopts servo closed-loop system, with high transmission precision and precise welding.

4. The fin spacing of the laser welded carbon steel finned tube can be ≤2.5mm, the heat dissipation area is increased by nearly 50% compared with the high frequency welded tube (the fin spacing ≥4.5mm), and the consumables per unit area are less, which can greatly reduce the replacement Heater volume.

Comments

Post a Comment